- sales@cognitivetechnologies.in

- #692 | Aiswarya Complex | Yelahanka New Town Bangalore | Karnataka | India

PROCESS DESIGNING

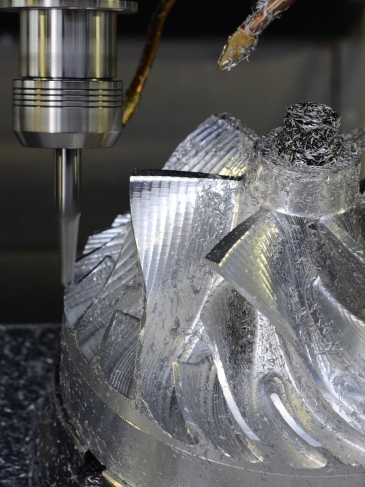

Precision Engineering through Comprehensive Process Planning for CNC Machining Components

In the realm of modern manufacturing, precision and efficiency are paramount. To meet these demands, we proudly present our specialized service: Process Planning for CNC Machining Components. At [Your Company Name], we understand that achieving excellence in CNC machining begins with meticulous process planning. Our service is designed to provide you with comprehensive, stage-by-stage process planning, ensuring the production of high-quality components with precision, efficiency, and reliability.

The Essence of Our Service

Customized Process Planning

Our service is built on the foundation of customization. We recognize that each CNC machining component is unique, with specific dimensional and quality requirements. Our dedicated team of experts collaborates closely with you to understand the intricacies of your project, starting with your provided drawing and 3D model.

In-Depth Failure Mode Analysis

At [Your Company Name], we leave no room for error. Our in-depth analysis of failure modes in CNC machining allows us to identify potential issues before they occur. By proactively addressing these challenges, we ensure that your machining process runs smoothly and efficiently, minimizing downtime and costly errors

Optimized CNC Machine Selection

Selecting the right CNC machine for each stage of production is critical to achieving the desired results. We leverage our expertise to determine which CNC machine is the most effective for each specific process, taking into account factors such as material, tolerances, and complexity.

Our Process Planning Expertise

Stage Drawings with Inspection Reports

Our meticulous approach to process planning includes the creation of stage drawings that outline each step of the machining process. These drawings not only guide the machining process but also serve as a visual reference for quality control. Inspection reports accompany each stage, ensuring that dimensions and quality standards are met at every step.

Documentation for Quality Assurance

To maintain rigorous quality control, we provide a suite of essential documentation, including:

- Route Card: A detailed roadmap of the machining process, ensuring that each stage is executed in the correct sequence.

- Process Capability and Control Methodology (PCCM): A comprehensive document outlining the control methods, tools, and equipment used at each stage to maintain consistency and quality.

- Control Plan: A proactive approach to quality assurance, outlining critical control points, inspection frequencies, and quality criteria.

- Process Failure Mode and Effects Analysis (PFMEA): A detailed analysis of potential failure modes, their effects, and the actions taken to prevent or mitigate them.

- Production Part Approval Process (PPAP) Documents: Ensuring that every component meets or exceeds the agreed-upon quality standards before full-scale production begins.

The [Your Company Name] Advantage

Holistic Approach

We offer a holistic approach to CNC machining process planning, addressing not only the technical aspects but also the quality assurance and documentation requirements. This comprehensive approach ensures that your components are produced with precision, consistency, and reliability.

Collaboration and Communication

Effective communication is at the core of our service. We maintain open lines of communication with our customers, providing updates, insights, and solutions throughout the process planning and machining stages. Our collaborative approach ensures that your expectations are met or exceeded.

Commitment to Excellence

At [Your Company Name], we are dedicated to excellence in CNC machining. Our process planning service is a testament to our commitment to delivering high-quality components on time and within budget. You can trust us to be your partner in achieving manufacturing excellence.

In conclusion, Process Planning for CNC Machining Components at [Your Company Name] is your gateway to precision engineering. With our customized approach, in-depth analysis, optimized machine selection, and comprehensive documentation, we ensure that your components are manufactured with the utmost precision and efficiency. Contact us today with your drawing and 3D model, and we'll provide you with the best CNC machining process for your unique component. Let us be your trusted partner in achieving machining excellence.

How does it works.

Step 1: Initial Consultation and Data Gathering

1.1. Project Initiation: The process begins when a customer contacts [Your Company Name] with their CNC machining component requirements.

1.2. Data Collection: Your team gathers essential project data, including the customer's provided drawing and 3D model, material specifications, tolerances, and quality requirements.

Step 2: Failure Mode Analysis and Feasibility Assessment

2.1. Failure Mode Analysis: Your experts conduct a thorough analysis of potential failure modes in CNC machining for the given component. This analysis identifies possible issues and challenges that need to be addressed in the process planning stage.

2.2. Feasibility Assessment: Based on the analysis, your team assesses the feasibility of machining the component, considering factors such as tooling, machine capabilities, and material properties.

Step 3: CNC Machine Selection and Process Planning

3.1. CNC Machine Selection: Your experts determine the most suitable CNC machines for each stage of the machining process, taking into account factors such as accuracy, speed, and tool compatibility.

3.2. Stage-by-Stage Process Planning: Your team creates a detailed stage-by-stage process plan that outlines each machining operation required to achieve the final dimensions of the component. This plan includes tool selection, cutting parameters, and machine settings.

Step 4: Stage Drawings and Inspection Reports

4.1. Stage Drawings: For each machining stage, your team creates stage drawings that visually represent the component at various stages of production. These drawings serve as a reference for both operators and quality control.

4.2. Inspection Reports: Alongside the stage drawings, inspection reports are generated to ensure that the dimensions and quality criteria are met at each stage of the machining process.

Step 5: Documentation for Quality Assurance

5.1. Route Card: A route card is prepared, detailing the sequence of operations and the order in which each stage of machining will be executed.

5.2. Process Capability and Control Methodology (PCCM): This document outlines the control methods, tools, and equipment used to maintain consistency and quality at each stage.

5.3. Control Plan: A comprehensive control plan is created, specifying critical control points, inspection frequencies, and quality criteria to be monitored during production.

5.4. Process Failure Mode and Effects Analysis (PFMEA): PFMEA is conducted, identifying potential failure modes, their effects, and the actions to prevent or mitigate them.

5.5. Production Part Approval Process (PPAP) Documents: PPAP documentation ensures that the component meets or exceeds the agreed-upon quality standards before full-scale production.

Step 6: Customer Collaboration and Approval

6.1. Customer Collaboration: Throughout the process planning phase, your team collaborates closely with the customer, sharing insights and seeking feedback to ensure alignment with their requirements.

6.2. Customer Approval: The customer reviews and approves the process plan, stage drawings, and quality documentation, ensuring that expectations are met.

Step 7: Execution and Quality Control

7.1. Machining Process: The approved process plan is executed on the selected CNC machines, with each stage closely monitored for adherence to the plan.

7.2. Quality Control: Rigorous quality control checks are conducted at each stage, ensuring that dimensions and quality standards are maintained.

Step 8: Final Documentation and Delivery

8.1. Final Documentation: Upon completion of the machining process, all documentation, including inspection reports and PPAP documents, is compiled for final review.

8.2. Delivery: The finished CNC machining component is prepared for delivery to the customer, along with the comprehensive documentation.

By following this comprehensive process flow, [Your Company Name] ensures the successful planning and execution of CNC machining processes for components, from initial data gathering to final delivery, while maintaining a focus on precision, efficiency, and quality assurance.