- sales@cognitivetechnologies.in

- #692 | Aiswarya Complex | Yelahanka New Town Bangalore | Karnataka | India

PRINCIPLES OF MACHINING

Principles of machining

In the realm of precision engineering and manufacturing, understanding the principles of machining is essential for producing high-quality components and ensuring efficient production processes. At [Your Company Name], we are proud to offer an intensive three-day training program that covers key aspects of machining, equipping participants with the knowledge and skills needed to excel in this field.

Key Highlights of the Program

Interpretation of Engineering Drawing

Bridging the Gap Between Design and Machining

One of the foundational skills in machining is the ability to interpret complex engineering drawings. Our program starts by demystifying these intricate documents, teaching participants how to understand dimensions, tolerances, symbols, and other critical information necessary for machining.

Layouts, Projections & Scale

The Language of Geometry

Geometry forms the basis of machining, and understanding layouts, projections, and scale is fundamental. We delve into these concepts, helping participants visualize and plan machining operations accurately.

Introduction to GD&T (Geometric Dimensioning and Tolerancing)

Precision at Its Core

GD&T is the language of precision in machining. We introduce participants to GD&T principles, teaching them how to apply geometric tolerances effectively and ensure components meet design specifications.

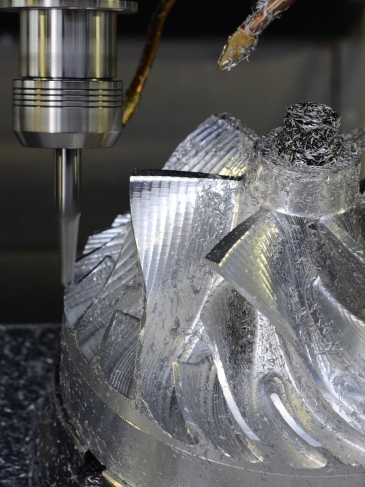

What is CNC Machines & its Types

Unlocking the Power of CNC Technology

CNC (Computer Numerical Control) machines are the backbone of modern machining. We explore the world of CNC technology, covering different types of CNC machines and their applications. Participants gain insights into the advantages of CNC machining over manual methods.

Intro to Manual Programming

Mastering the Fundamentals

Manual programming is a skill that sets the foundation for CNC operation. Our program includes hands-on sessions where participants learn the basics of manual programming, enabling them to create CNC programs from scratch.

Practical Project

Putting Knowledge into Practice

The culmination of our training program is a practical project where participants apply the principles they’ve learned. This hands-on experience reinforces their understanding of machining concepts, from reading engineering drawings to programming CNC machines.

Why Choose Our Training Program?

Comprehensive Curriculum

Our program covers a wide range of topics, ensuring that participants gain a holistic understanding of machining principles. From interpreting engineering drawings to hands-on experience with CNC machines, we leave no stone unturned.

Experienced Instructors

Our instructors are industry experts with a wealth of experience in machining. They bring real-world knowledge and practical insights to the training, making the learning experience engaging and informative.

Hands-On Learning

We believe in learning by doing. Our program includes practical exercises and a final project, allowing participants to apply their knowledge in a real-world context and build confidence in their machining skills.

Career Advancement

Whether you’re new to machining or looking to enhance your existing skills, our training program opens doors to new career opportunities. Machining professionals equipped with our training are highly sought after in the industry.

Certification

Upon successful completion of the program, participants receive a certification from [Your Company Name], a testament to their expertise in machining principles and their ability to contribute effectively to the world of precision engineering.

In conclusion, our three-day training program on the Principles of Machining is designed to empower participants with the knowledge and skills necessary to excel in the world of precision manufacturing. From understanding engineering drawings to practical experience with CNC machines, our comprehensive curriculum sets the stage for a successful career in machining. Join us in mastering the art of machining and shaping the future of precision engineering.