What Set This Project Apart? – On-Site Commitment & Prove-Out

What truly set this project apart was the Dedication and Ownership shown by our Engineering Team. Beyond Digital Programming and Simulation, our Engineers went On-Site to the Customer’s Facility, stood in front of the CNC Machines, and personally Proved Out Each Component—ensuring flawless Transition from Digital Models to Physical Parts.

Key Deliverables

- End-to-End CAM Programming for 40+ Aero-Structural Components

- Vericut Simulation for Collision-Free and Optimized Toolpaths

- Stage Model Creation for Process Clarity

- Custom Fixture Design and Validation

- On-Site Machine Prove-Out by Expert Engineers

Timeline Achievement

Despite the Complexity and Volume, all deliverables were completed Within 2 Months—demonstrating our Agility, Discipline, and Deep Domain Knowledge in High-Mix, Low-Volume Aerospace Manufacturing.

Impact

- Reduce Lead Times Significantly

- Enhance Machining Accuracy through Simulation

- Ensure Seamless Transition from Digital to Physical Manufacturing

- Scale Operations with Confidence

Looking Ahead

This project showcases our capability to support Mission-Critical Aerospace Programs through Agile Engineering, Digital Validation, and Hands-On Manufacturing Support. As our partnership with this MNC Aerospace Leader grows, we continue to bring Speed, Precision, and Commitment to Every Engagement.

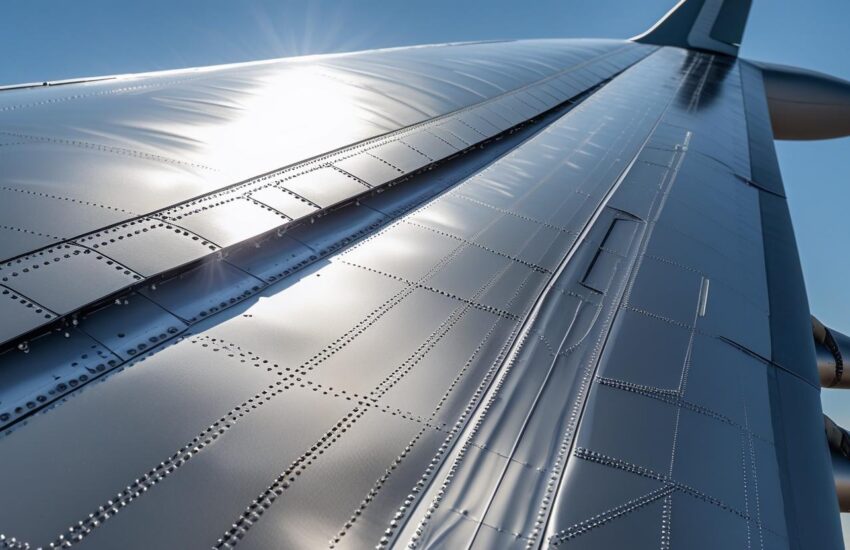

Accelerated Programming & Simulation for Complex Aero-Structural Components

Client Profile

A Multinational Aerospace Manufacturer based in Bangalore, specializing in Structural and Landing System Components for major Global OEMs. Known for delivering Complex, High-Tolerance Parts for Critical Aerospace Assemblies.

Client Challenge

Deliver End-to-End CNC Programming, Fixture Design, and Full Simulation for over 40 Complex Aero-Structural Components—across Diverse Materials and Geometries—Within Just 2 Months.

Project Overview

At Cognitive Engineering Technologies Pvt. Ltd., we successfully executed a Precision-Driven, Time-Sensitive Manufacturing Engineering Solution for this esteemed Aerospace client. Leveraging our Expertise in CAM Programming, Fixture Design, and Digital Simulation, we ensured each part was delivered with Speed, Accuracy, and Reliability.

Project Highlights

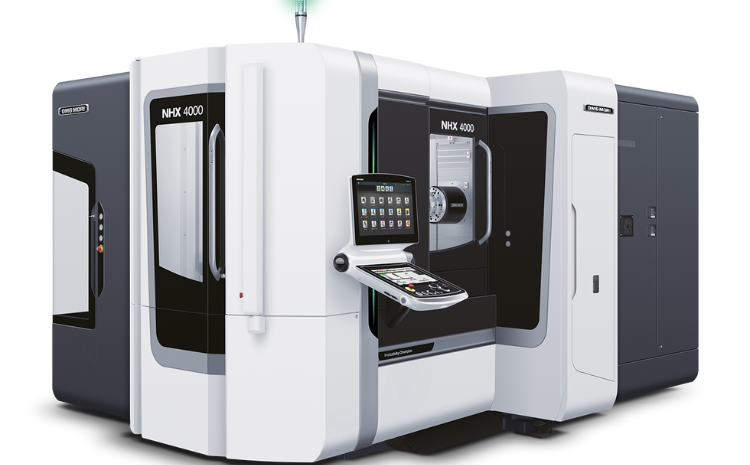

- CAD/CAM Platform: Siemens NX

- Verification: Vericut

- Machinery Used: DMG 4-Axis

Scope: Programming, Fixture Design, Stage Model Creation, and Complete Simulation