Projetc Highlights

- Materials Machined: Aluminum 7075 and Aluminum 2024

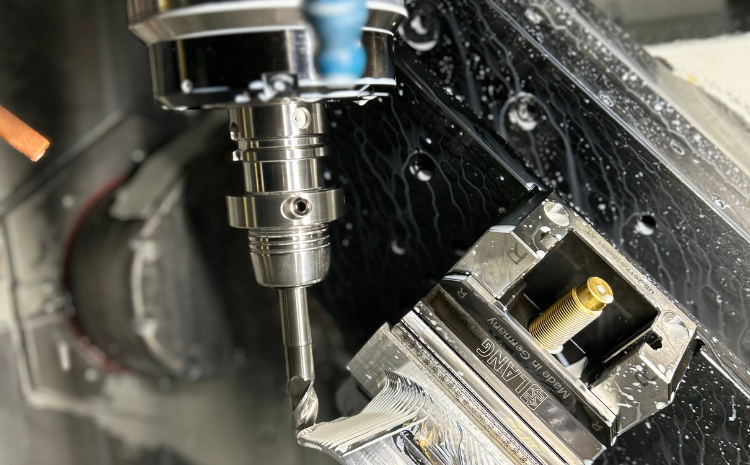

- Unified Fixture Platform: All parts ran on a single fixture Concept with a common work offset, enabling faster changeovers and improved reliability

- Standardized Tooling: a 26-tool configuration used across multiple automation cells for consistent performance

- World-Class CNC Machines: Makino slim 3N & 5N Machines with HSK spindles and 16,000 RPM—ensuring Machining Excellence

- Single Work Offset: All components were successfully machined using one work offset, simplifying the entire process flow

A Contribution to Aerospace Manufacturing

Today, all components produced under this program are in full production, being delivered to major OEMs in the Aerospace industry. It’s a moment of pride to know that Cognitive has played a role in supporting global aviation, helping deliver precision components that meet the highest quality standards.

Overcoming Complex Challenges with Engineering Excellence

What made this project even more significant was the criticality of the components involved. We machined parts with thin walls, intricate profiles, and geometries prone to bending—all of which required advanced fixture design, adaptive toolpath strategies, and real-time problem solving.

Choosing just 26 common tools to machine over 100 unique parts was a true Engineering challenge. It demanded sharp teamwork, intelligent planning, and innovative thinking. Smart use of combination tools and optimization techniques helped us take one step ahead—delivering results with consistency, accuracy, and speed.

One Setup. Zero Compromise. 100+ Aerospace Parts in Automation

At Cognitive Engineering Technologies, we take immense pride in redefining CNC Machining Excellence. Our team successfully programmed and Automated over 100 unique Aerospace components using just 26 precision tools—a standout accomplishment that reflects our deep Engineering capabilities, process mastery, and commitment to smart Manufacturing.

Partnership for Performance

This achievement was realized through a strong collaboration with a leading Aerospace company based in Bangalore. Our advanced automation setup is now deployed, validated, and delivering results on the production floor, supporting real-time Aerospace Manufacturing.

Scope of Work: Complete Engineering Ownership

Cognitive was entrusted with an end-to-end scope, Process Planning Fixture Desigin Stage Drawing Inspection Reports CNC Programming Virtual Simulation taking full responsibility for:

- Process Planning

- Fixture Design

- Stage Drawing

- Inspection Reports

- CNC Programming

- Virtual Simulation

Our Engineers also handled the entire prove-out process for all components—ensuring each part met Aerospace standards. We worked closely with Quality delegates throughout the journey, transforming complex requirements into production-ready solutions.

Grateful and Inspired

We sincerely thank our customer for their trust and confidence in our capabilities. At Cognitive, we believe in one powerful principle: “Trust Us.”

A heartfelt thank you to our dedicated Engineering and Manufacturing team—your commitment, creativity, and resilience made this success possible.

We’re proud of the impact we’ve created, and even prouder to say:

Cognitive is contributing to the future of Aerospace.